In the rapidly evolving landscape of technology, transformers play a crucial role in various applications, from power distribution to electronic devices. As these transformers are essential components in ensuring the smooth functioning of many systems, their longevity is a critical factor. One key aspect that can significantly influence the lifespan of transformers is diagnostic testing. This article explores the proactive measures implemented through diagnostic testing and their profound impact on transformer longevity.

Understanding Transformers:

Before delving into diagnostic testing, it's essential to comprehend the significance of transformers. These devices are instrumental in altering voltage levels in electrical circuits, facilitating the efficient distribution of power across various applications. Transformers are omnipresent in power grids, industrial machinery, and electronic appliances, making them indispensable for modern living.

Challenges to Transformer Longevity:

Transformers are subject to various stressors that can compromise their functionality and longevity. Overloading, voltage fluctuations, and environmental factors like temperature and humidity are some of the challenges transformers face. Over time, these stressors can lead to degradation, insulation breakdown, and ultimately, failure. The consequences of transformer failure can be severe, causing disruptions in power supply, equipment damage, and costly downtime.

The Role of Diagnostic Testing:

To mitigate the risks associated with transformer failures, diagnostic testing has emerged as a proactive solution. Diagnostic testing involves a series of assessments and analyses aimed at evaluating the health and performance of transformers. This approach enables early detection of potential issues, allowing for timely intervention and preventive measures.

Key Diagnostic Tests:

- Dissolved Gas Analysis (DGA): DGA is a widely used diagnostic test that involves analyzing gases dissolved in the transformer oil. Abnormal gas levels can indicate various issues, such as overheating, partial discharge, or insulation degradation. Early detection through DGA allows for targeted maintenance, preventing further deterioration.

- Power Factor Testing: Power factor testing assesses the efficiency of insulation in a transformer. A declining power factor can signal insulation problems, which, if left unaddressed, can lead to catastrophic failures. Regular power factor testing helps identify potential issues early on, ensuring timely repairs or replacements.

- Partial Discharge Measurement: Partial discharge is a phenomenon that can occur within a transformer, indicating insulation weaknesses. By measuring and monitoring partial discharge, diagnostic testing helps identify areas of concern, enabling proactive measures to strengthen insulation and prevent failures.

- Turns Ratio Testing: Turns ratio testing evaluates the turns ratio of the transformer windings. Any deviation from the expected ratio can indicate winding or core issues. Timely identification of such issues through turns ratio testing allows for corrective action, preventing further damage.

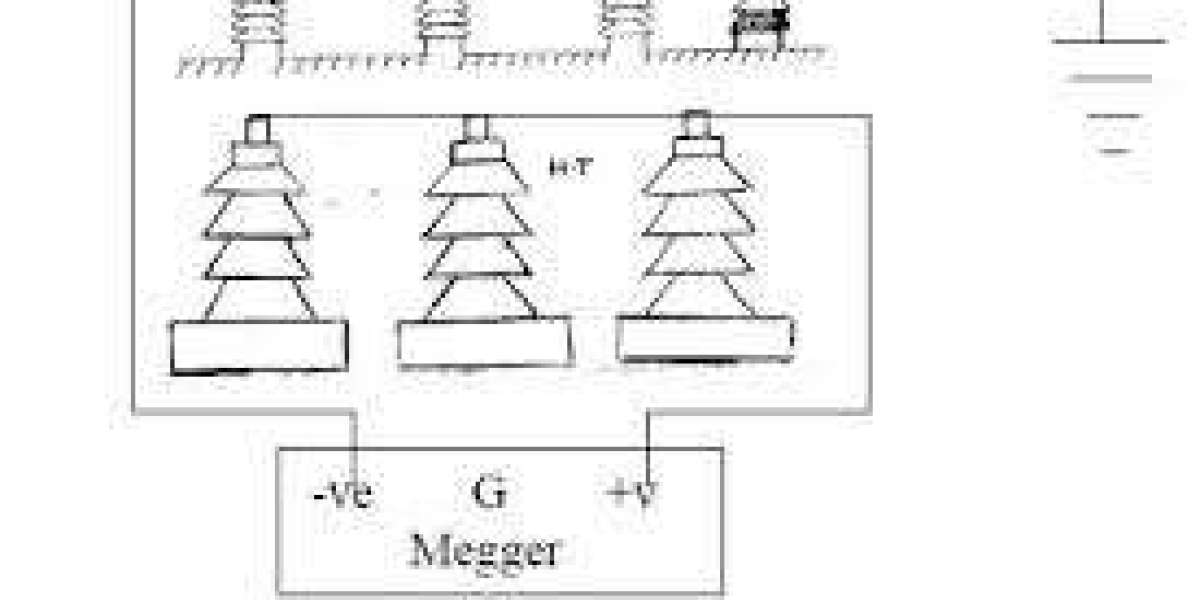

- Insulation Resistance Testing: Insulation resistance testing measures the resistance of the insulation material. A decrease in insulation resistance can be a sign of moisture ingress or insulation deterioration. Regular testing helps detect these issues early and allows for targeted repairs to extend the transformer's lifespan.

Impact on Transformer Longevity:

Implementing diagnostic testing as part of a proactive maintenance strategy has a profound impact on transformer longevity. By identifying potential problems before they escalate, diagnostic testing helps extend the operational life of transformers. The financial implications of proactive maintenance are significant, as it reduces the likelihood of unexpected failures, minimizing repair costs and downtime.

- Cost Savings: Proactive diagnostic testing enables early detection of issues, allowing for targeted and cost-effective maintenance. Addressing problems at their inception is considerably more economical than dealing with the aftermath of a transformer failure, which may involve extensive repairs or even replacement.

- Reduced Downtime: Transformer failures often result in downtime, impacting the operations of industries, power grids, and various applications. Diagnostic testing helps minimize downtime by addressing issues before they lead to complete failure. This is particularly crucial in sectors where uninterrupted power supply is essential.

- Improved Reliability: Regular diagnostic testing enhances the overall reliability of transformers. Knowing the health and condition of transformers allows for informed decision-making regarding maintenance schedules and replacement timelines. This, in turn, contributes to the overall stability and reliability of power systems.

- Enhanced Safety: Transformer failures can pose safety risks, including the potential for fires and other hazardous situations. Proactive diagnostic testing reduces these risks by identifying and addressing issues early on, ensuring a safer operating environment.

- Environmental Impact: The environmental impact of transformer failures can be significant, especially if they lead to oil spills or other hazardous situations. By preventing failures through diagnostic testing, the environmental footprint associated with transformer maintenance and replacements is minimized.

Challenges in Implementing Diagnostic Testing:

While diagnostic testing offers numerous benefits, its implementation comes with certain challenges. One primary challenge is the initial investment in testing equipment and training for personnel. However, it's essential to view this as a strategic investment that pays off in the form of extended transformer lifespan and reduced long-term maintenance costs.

Additionally, integrating diagnostic testing into existing maintenance practices may require organizational changes and a shift in mindset. Some entities may still follow a reactive maintenance approach, addressing issues only when they arise. Convincing stakeholders of the long-term benefits of proactive measures can be a hurdle but is crucial for the overall health of the transformers and the systems they support.

Conclusion:

Proactive measures, particularly in the form of transformers diagnostic testing, are paramount for ensuring the longevity and optimal performance of transformers. The impact of these measures extends beyond cost savings and reduced downtime to encompass improved reliability, enhanced safety, and a positive environmental footprint. As technology continues to advance, embracing diagnostic testing as an integral part of transformer maintenance is not just a choice but a necessity for industries, power utilities, and any entity relying on the seamless operation of electrical systems. By prioritizing proactive measures, we pave the way for a more resilient and sustainable future in the realm of transformers and electrical infrastructure.